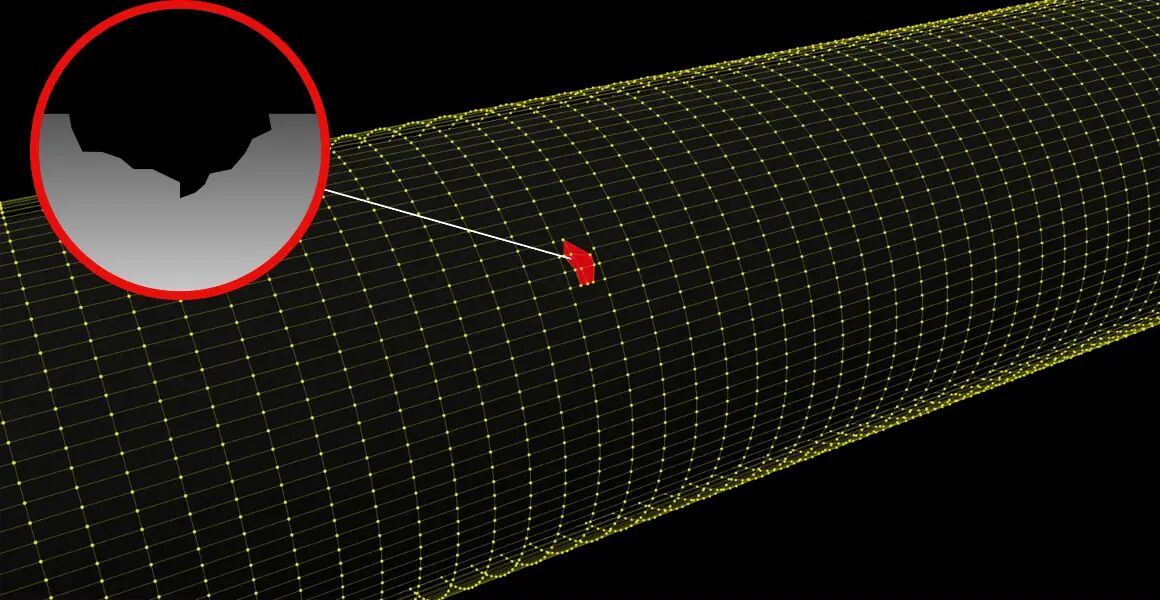

Key Characteristics

- A non‑capacitive, ohmic current attenuation at a coating defect reveals bare steel in soil contact, confirming the corrosion cell is active and driving metal loss.

- CMI geo‑tags each corrosion hotspot on the pipeline so crews can excavate, re‑coat, or adjust CP only where intervention is truly needed.

- Eliminates unnecessary digs, concentrates costs on real threats, and extends asset life without disrupting product flow.

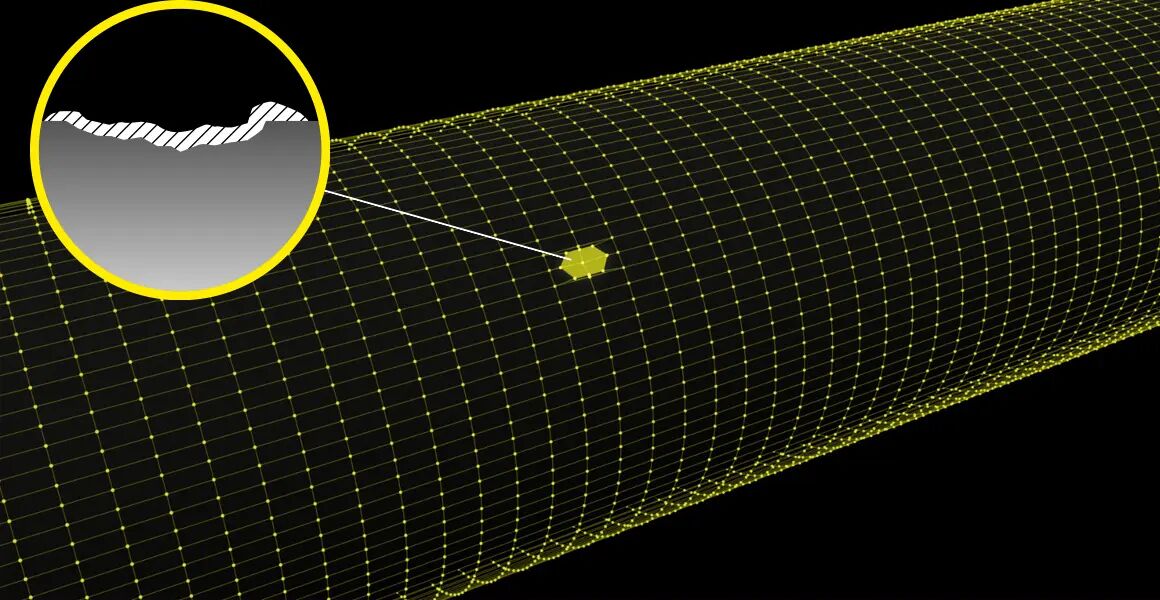

Key Characteristics

- A capacititve current leakage at a defect signals a calcareous film on the steel surface, proving the corrosion cell is electrically blocked and passive.

- Log GPS referenced locations in your ECDA programme; routine potential checks or periodic CMI sweeps are sufficient—no urgent digs or CP adjustments required.

- Avoids unnecessary excavation costs and keeps product flowing while maintenance crews focus on real threats elsewhere.