Explore our Services

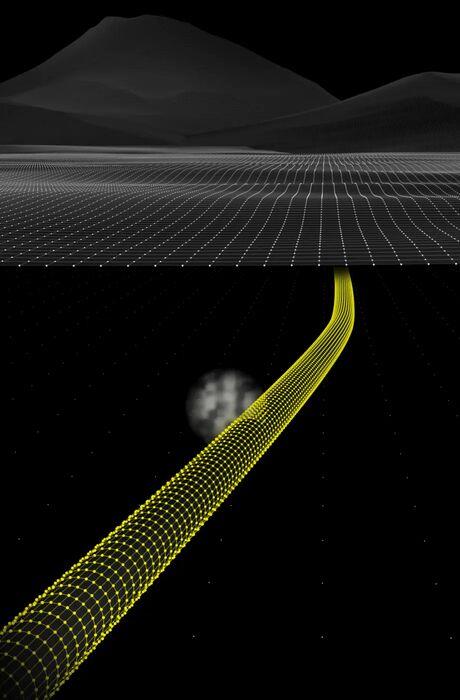

Across all Infrastructure

EMPIT’s service portfolio covers a wide range of inspection tasks from aboveground. Learn how Current Magnetometry Inspection (CMI) technology is applied across industries, terrains and geometries.

Corrosion Detection

Corrosion is a persistent threat to pipeline integrity—where EMPIT’s non‑intrusive CMI makes the difference. Our method delivers actionable insights for unpiggable pipelines by distinguishing active from passivated corrosion, providing a reliable basis for informed decisions.

Pinpoint and rank active corrosion hotspots down to < 1 mm², enabling targeted maintenance, repair and replacement planning where it is necessary.

Integrates seamlessly with your External Corrosion Direct Assessment (ECDA), Pipeline Integrity Management Systems (PIMS) and other workflows.

Aboveground CMI inspects buried, unpiggable pipelines without pigging, ILI, excavation or shutdown—dramatically reducing risk and cost.

Field-Proven Services

for Pipeline Assessment

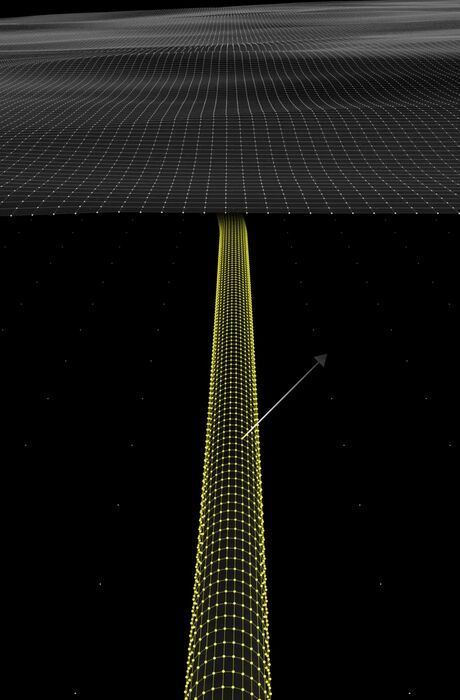

How does it work?

Current Magnetometry Inspection

The AC Current Source

We couple an intelligent signal‑generator to existing CP posts and inject a multi‑frequency AC waveform (2 Hz – 2 kHz) into the line.

This creates a predictable magnetic vortex that:

-

Isolates the pipe – each frequency interacts differently with steel, soil and foreign structures, so the pipe’s signature stands out cleanly.

-

Exposes corrosion electrochemistry – frequency‑specific leakage patterns reveal whether a holiday is actively corroding or already passivated.

-

Keeps flow online – the AC drive is non‑intrusive; no pigging, no excavation, no shutdown, and the CP system remains in normal operation.

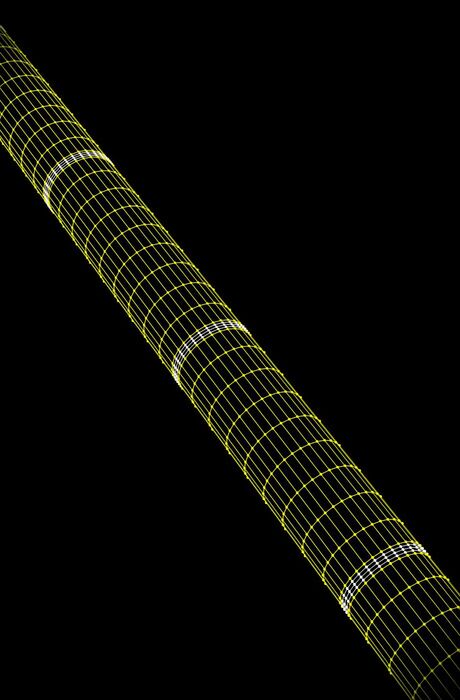

Signal Detection

Air‑, water‑ and ground‑based arrays carry up to 70 tri‑axial sensors, sampling the magnetic field 20 000 times per second.

The wide sensor array captures the field vector in all three dimensions while simultaneously logging:

-

RTK‑grade position & altitude – centimetre‑level GNSS plus lidar / sonar give absolute XYZ of pipeline, groundlevel and depth of cover.

-

Device attitude – pitch, roll and sensor‑to‑surface distance ensure vector data are resolved correctly.

This combination makes CMI the most precise platform worldwide for 3‑D magnetic mapping, depth‑of‑cover verification and sub‑centimetre coating‑defect localisation on complex or unpiggable assets.

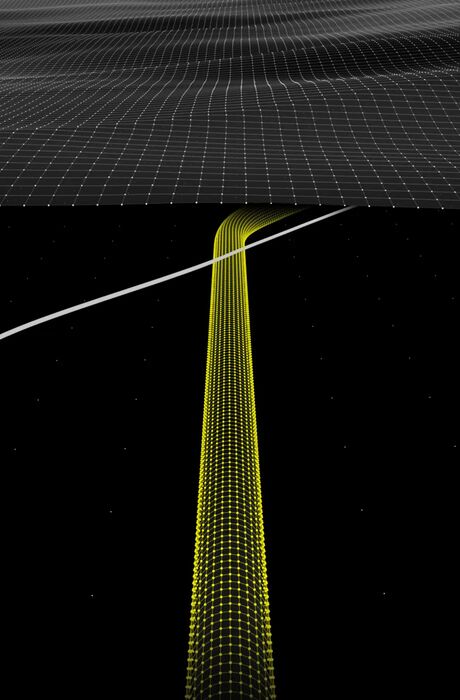

Data Transfer and Processing

Every raw waveform streams through a cloud where deep‑fusion AI and machine‑learning models clean, align and interpret the data.

Key parameters feed back to the signal‑generator within milliseconds, enabling it to:

-

Auto‑tune signal‑to‑noise for changing soil and interference conditions.

-

Normalise current & field on the fly, locking each reading to its exact excitation value.

The tight time‑correlation between injected current and measured response underpins reliable corrosion‑risk grading, high‑accuracy 3‑D pipe mapping and even bending‑strain analytics—delivered before the crew leaves the right‑of‑way.

Materials We Inspect

with CMI

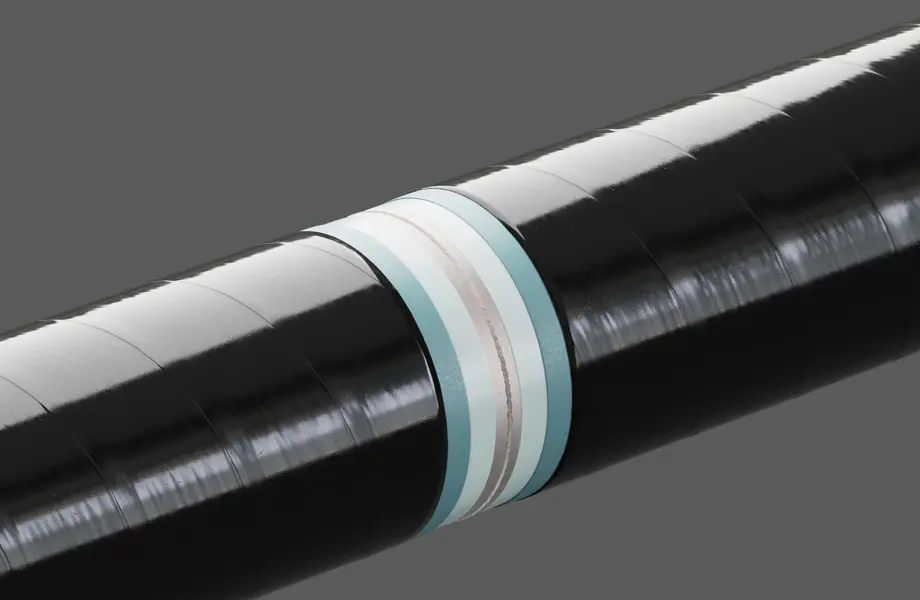

Steel

Standard for oil, gas, and chemicals

EMPIT detects corrosion, coating defects, 3D position, and strain. Trusted by 100+ operators.

Ductile Iron

Used in water networks

CMI enables surface-based depth of cover and geometry assessment to identify high-risk areas — including corrosion-prone zones.

Grey Iron

Still active in legacy systems

EMPIT inspects for corrosion, ramaining life time, and geometry for a safe pipeline operation strategy.